1. Product Overview

Taizhou Fupusi Machinery Co., Ltd. delivers the S Series semi-automatic blow molding machine, designed for cost-efficient, space-saving production of PET bottles (100ml–30L).

Key Features:

✔ User-friendly: Intuitive controls & minimal training required

✔ Low maintenance: Robust construction reduces downtime

✔ Versatile: Shapes bottles for water, soda, oils, cosmetics, and pesticides

2. Technical Specifications

- Capacity: 100ml to 30L

- Applications:

- Beverages: Mineral water, carbonated drinks

- Household: Edible oils, detergents

- Specialty: Cosmetics, pesticide containers

3. Market Positioning

Ideal for:

- Startups & SMEs seeking affordable entry into blow molding

- Facilities with limited floor space

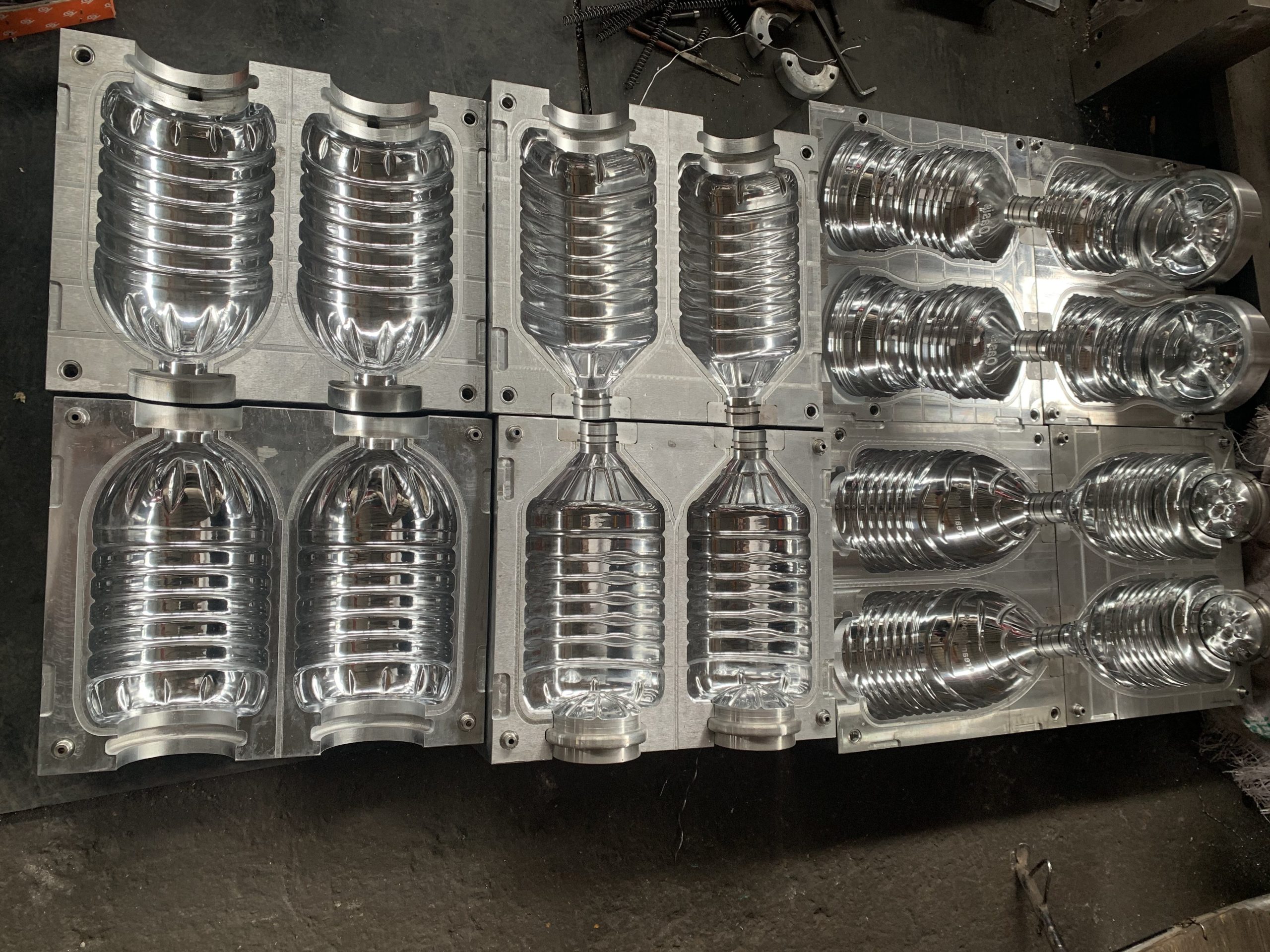

- Producers requiring quick mold changes for multi-product lines

4. Competitive Edge

Compared to competitors, the S Series offers:

Proven reliability in harsh production environments

40% lower operational costs

Compact footprint (20% smaller than industry average)

Semi-auto for 2L

Semi-auto for 3L to 5L

Semi-auto for 10L to 20L

Taizhou Fupusi Machinery Co., Ltd. has always been striving for innovation, holding the flag of high quality, accuracy reliability, and competitiveness.

about the semi-auto model, it has a series as follows

1, 2L machine 2 cavity

2, PC machine (1 cavity and 2 cavities)

3, PP machine (1 cavity and 2 cavities)

4, 5L machine (1 cavity and 2 cavities)

5, 10L machine 1 cavity

6, 20L machine 1 cavity

7, 30L machine 1 cavity

|

项目 |

Item |

unit |

FPSB3L |

FPSB2L-4 |

FPSB5L-1 |

FPSB5L-2 |

FPSB10L-1 |

FPSB20L |

|

|

瓶型规格 Bottle type Specification |

瓶子最大容量 |

Max. Volume |

L |

3 |

1.2 |

5 |

5 |

10 |

20 |

|

理论产量 |

Output |

PCS/H |

700-900 |

1500-1800 |

350-450 |

500-600 |

250-350 |

200-280 |

|

|

最大瓶子高度 |

Max. Height |

MM |

300 |

300 |

400 |

400 |

450 |

550 |

|

|

最大瓶子直径 |

Max. Diameter |

MM |

135 |

105 |

180 |

180 |

220 |

260 |

|

|

瓶子口径 |

Neck Size |

MM |

100 |

38 |

120 |

140 |

38-65 |

38-65 |

|

|

腔数 |

Cavity |

PCS |

2 |

4 |

1 |

2 |

1 |

1 |

|

|

吹瓶机规 Blower Specification |

动作压力 |

Action Pressure |

MPa |

0.8-1.0 |

0.8-1.0 |

0.8-1.0 |

0.8-1.0 |

0.8-1.0 |

0.8-1.0 |

|

吹气压力 |

Blowing pressure |

MPa |

2.5-2.8 |

2.5-2.8 |

2.5-2.8 |

2.5-2.8 |

2.5-2.8 |

2.5-2.8 |

|

|

机器尺寸 |

Blower size |

M |

1.45*0.65*1.6 |

1.95*0.85*1.6 |

1.75*0.65*1.6 |

1.95*0.85*1.6 |

1.95*0.65*1.6 |

2.2*0.75*1.75 |

|

|

机器重量 |

Blower weight |

T |

0.65 |

0.82 |

0.75 |

0.82 |

0.94 |

1.15 |

|

|

烘箱规格 Oven Specification |

灯管数量 |

Number of tubes |

PCS |

28 |

28 |

40 |

40 |

40 |

60 |

|

灯管功率 |

Power of tubes |

KW |

0.6 |

0.6 |

0.8 |

0.8 |

0.8 |

0.8 |

|

|

加热功率 |

Heating power |

KW |

16.8 |

16.8 |

32 |

32 |

32 |

48 |

|

|

烘箱尺寸 |

Oven size |

M |

1.8*0.65*1.4 |

1.8*0.65*1.4 |

2.25*0.65*1.4 |

2.25*0.65*1.4 |

2.4*0.65*1.4 |

2.7*0.7*1.6 |

|

|

烘箱重量 |

Oven weight |

T |

0.3 |

0.3 |

0.33 |

0.33 |

0.35 |

0.38 |

|

|

Actual output depends on bottle shape and preform qualification, the above technical parameters are subject to continual updates, please rake the real product as the base. |

|||||||||